OUR TECHNOLOGY

On this page you may learn in detail about our unique technology, components and dimensions of engineered flooring and its durability

It Takes Innovation to Excel

At the heart of our company’s success lies our unwavering commitment to innovation. Our relentless pursuit of cutting-edge technology sets us apart from the competition, enabling us to deliver products that exceed expectations. Without innovation, we simply wouldn’t have the capabilities to create the remarkable solutions that define our brand.

Through continuous research and development, we push the boundaries of what’s possible in our industry. Our investment in innovative technology allows us to stay ahead of the curve, constantly evolving and adapting to meet the ever-changing needs of tomorrow.

But innovation is more than just a buzzword for us—it’s a fundamental principle that drives our entire operation. It’s what empowers us to tackle complex challenges, push past limitations, and revolutionize the way our products are designed, produced, and experienced by our customers.

By embracing innovation at every turn, we not only stay competitive in the marketplace but also pave the way for a future where possibilities are limitless. Our dedication to pushing the boundaries of what’s possible ensures that we continue to lead the industry forward, delivering unparalleled products and experiences that leave a lasting impression.

The Best in the Industry - Engineered Flooring

At our company, we pride ourselves on leveraging not only our own technical advancements but also industry innovations like engineered flooring. This flooring solution represents a significant stride towards sustainability, as it allows us to conserve precious wood resources while ensuring technical stability. By utilising lesser amounts of precious wood in the plank structure, engineered flooring allows us to preserve more of the oak and other rear wood resources, making it an environmentally conscious choice.

Moreover, its innovative construction provides technical stability, reducing the risk of twisting and warping that can occur with solid wood flooring. This stability ensures longevity and durability, offering peace of mind to our customers while minimizing the need for replacements. With engineered flooring, we’re not just saving resources—we’re also delivering superior quality and performance for a sustainable future.

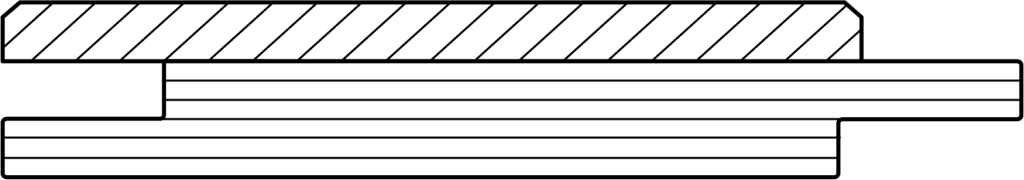

Components and Dimensions

Wear layer thickness | 5,5 mm (0.21’’)

Core layer thickness | 12 mm (0.47’’)

Core layer : Baltic birch plywood

Overall thickness : 17,5 mm (0.68’’)

Length : 500 – 2950 mm (20’’ – 10’)

Width : ca 100 – 450 mm (4’’ – 17.7’’)

Overall weight up to : 13 kg/m2

Thermal transmittance : 0,16 λ (W/mK)

Fire resistance class : Dfl – s1

Formaldehyde emission : E1

Moisture content : EN 13183, 8% ± 2%

Our engineered flooring boasts a meticulous composition, comprising 5.5mm of premium hardwood seamlessly integrated with 12mm of Baltic birch plywood of the highest quality. This fusion creates robust superstructure boards with an overall thickness of 17.5mm. Upon secure adhesive application to a suitably prepared surface, our finishes achieve a final thickness of 18mm.

At present, we provide a selection of three hardwood options: oak, ash, and walnut. To cater to varying ambiance preferences, we offer three purity levels: rustic, nature, and select. Rustic boards feature a rich saturation of natural elements, while select boards offer a cleaner appearance. For further details and visual examples, please refer to the Collection page.

The technical specification of the product confirms with the requirements and contains the product compliance description pursuant to the EN 14342 : 2013 standard.

EADGAR BERSOHN hereby confirms that the floorboards comply with the 89/106/EEC Directive for Construction products.

Built to Last Generations

In an industry where standards often prioritize economy over durability, we’ve set out to redefine expectations. While the industry average for engineered flooring typically features a hardwood layer of less than 3 mm, our commitment to excellence drives us to nearly double that, with a substantial 5.5 mm layer of premium hardwood. This significant increase in hardwood thickness translates to a flooring lifespan nearly twice as long as the industry norm.

As with every wooden floor, in order to maintain the original appeal, it’s advised to refinish the surface at least every 10 years. This proactive approach ensures that the floor retains its initial luster and beauty. With a refinishing interval of 10 years and considering a minimum of 1 mm hardwood layer for the average-traffic areas, we’ve ensured that our floors can last for generations – they can endure over a century of use while still maintaining their durability and charm.